Conversion of two wings of the Lycée Michel Lucius

A range of circular solutions in Luxembourg

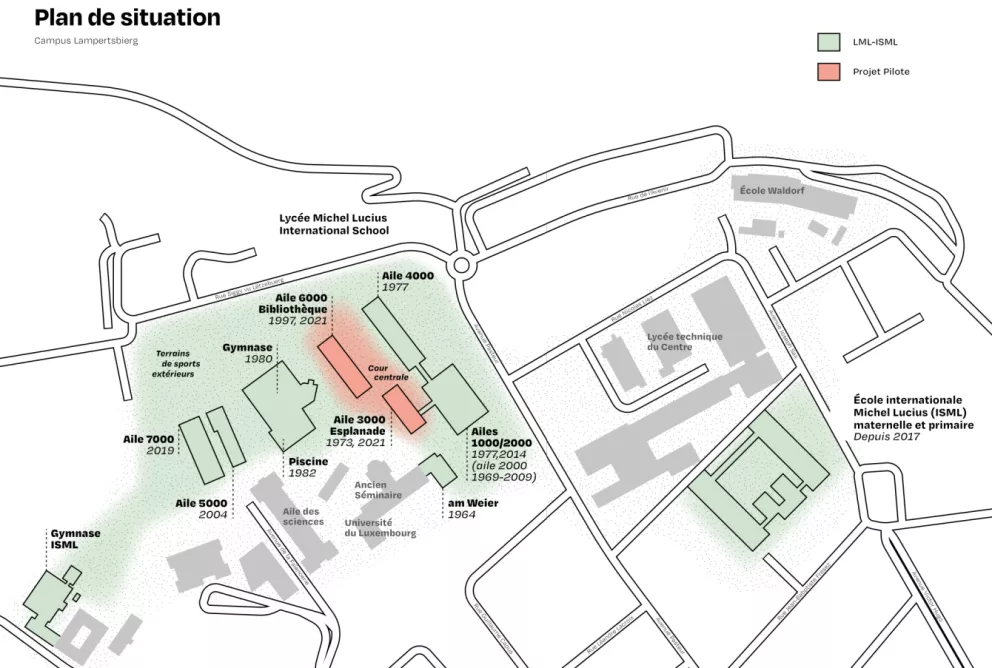

The Michel Lucius school campus, located in Luxembourg Limpertsberg, comprises around ten buildings constructed gradually since 1969 to meet the growing need for school infrastructure. The project presented here involves the conversion of two buildings: the 3000 wing (dating from 1973) and the 6000 wing (dating from 1997). The project took place between 2018 and 2021. The approach chosen by the client and the design team gave pride of place to circular strategies such as maintaining what already exists, reclaiming and reusing materials, and high-quality recycling.

Figure 2. Map of the Lycée Lucius Michel campus and location of the two wings where work was carried out.

A different approach for each wing

Although they were built almost 30 years apart, the 3000 (built in 1973) and 6000 (built in 1997) wings share some similarities. They are both highly prefabricated buildings: the first with a metal frame (Fillod system), the second in wood. Both also failed to meet current standards, which is why they had to be converted.

The approach for each wing is quite different. What they all have in common, however, is that they aim to make the most of the material resources available on the site.

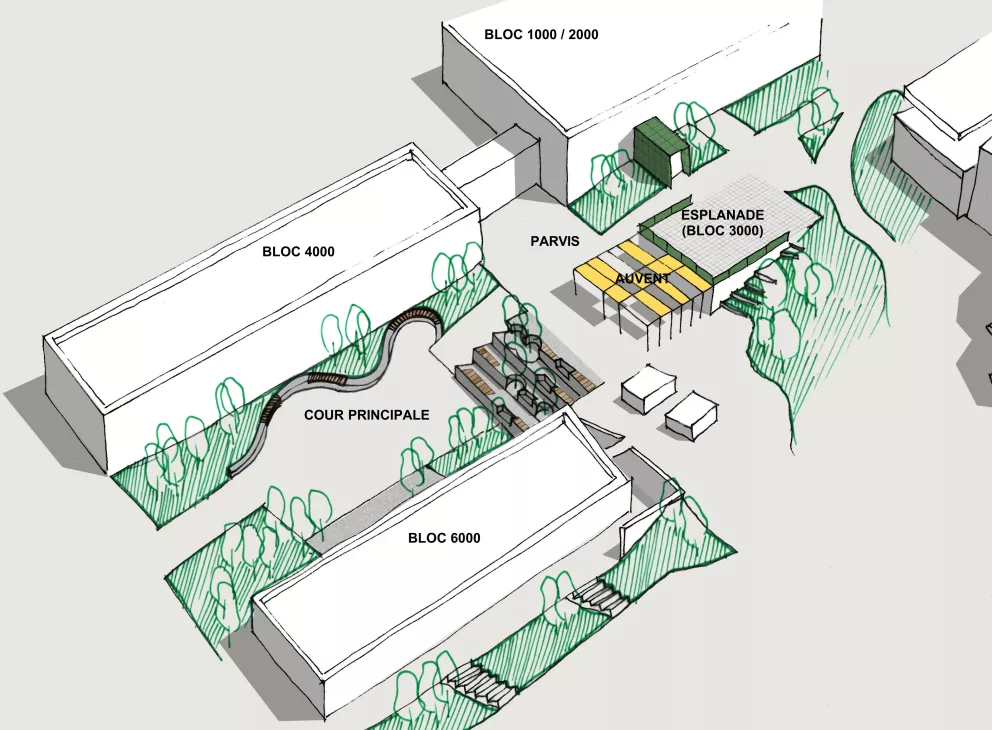

The 3000 wing was largely demolished. Only the basement (semi-buried) was kept in place. It now serves as a workshop and storage area for the campus technical service. What was once the floor of the first level has become a flat roof, transformed into an esplanade accessible from the upper part of the site.

During the dismantling of the building, part of the original steel structure was reclaimed. Some elements were reused to build a canopy next to the esplanade. Other elements salvaged during this work were used to renovate the 6000 wing (in particular a batch of sheet metal) and to fit out the esplanade (as in the case of the olive green façade panels).

Figures 3 and 4.

Schematic diagram of the conversion of the 3000 wing. The semi-buried basement is maintained, the roof becomes an esplanade and the metal framework is reused to build a canopy.

Wing 3000 after its transformation. In the foreground of the photo, you can see the landscaping work and the site's accessibility (access ramp).

As regards the 6000 wing, most of the original building has been kept in place. A detailed feasibility study concluded that this solution was economically and environmentally beneficial. The programme was adapted, however, as the building now houses a library and reading centre.

This conversion required the partition walls to be opened up. Most of the interior walls separating the classrooms and some of the floors were demolished. The original volume has not changed, but the interior has become more spacious, thanks in particular to the double-height sections (which also play a technical and climatic role, as they act as a buffer zone for smoke in the event of fire and also store warm air to prevent the risk of overheating).

Figure 5: Creation of a double-height volume in the 6000 wing, which now houses the Lycée Michel Lucius school library.

A range of circular solutions

The renovation project gives pride of place to circular solutions.

Retaining the existing building

As explained above, the project retained every part of the building that could be kept as such. It is notably the case in the wing 6000. There a feasibility study compared three scenarios:

- Integral demolition of the existing volume and re-construction of a new, identical building.

- Integral demolition of the existing volume and re-construction of a smaller volume, for the library only.

-

Conversion of the existing volume into the library (and additional classrooms for extracurricular activities).

This third scenario was the most beneficial.

Firstly, in terms of functionality, this scenario made it possible not only to accommodate the library but also to keep 10 classrooms (out of the original 24) for extracurricular activities. Keeping these rooms available is a direct consequence of the project to retain the existing building. In a demolition-reconstruction scenario, these rooms would most likely not have been rebuilt since, strictly speaking, they were not directly part of the library programme.

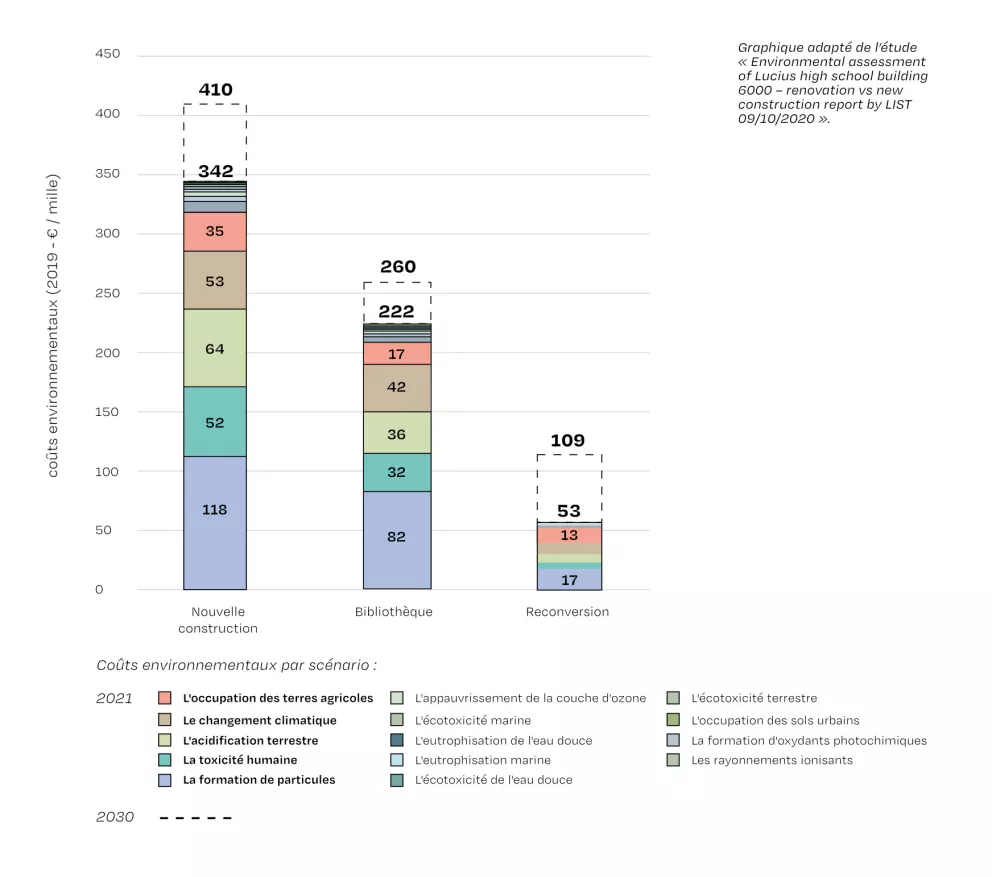

Secondly, in terms of material economy, this solution was (by far) the most economical in terms of raw materials and the most moderate in terms of waste production. The work involved in converting the existing building required 72 tonnes of materials (compared with 2,200 tonnes for the construction of a new library and 2,400 tonnes for the construction of a new building of identical size to the original). This solution also reduced the production of demolition waste by 79%.

In terms of greenhouse gas emissions, a life cycle assessment (LCA) carried out by a public research centre concluded that converting the existing building would result in savings of 458 to 792 tonnes of CO2 equivalent compared with the first two scenarios. Similar gains were found for other environmental and health impacts (particle formation, human toxicity, acidification of land, occupation of agricultural land, etc.).

Figure 6. Comparison of the environmental impact of the three solutions studied. The conversion of the existing building (far right) is by far the most advantageous.

Finally, converting the existing building also proved to be the quickest and least expensive option.

This type of conversion does, however, require the various parties involved to adapt their practices to some degree.

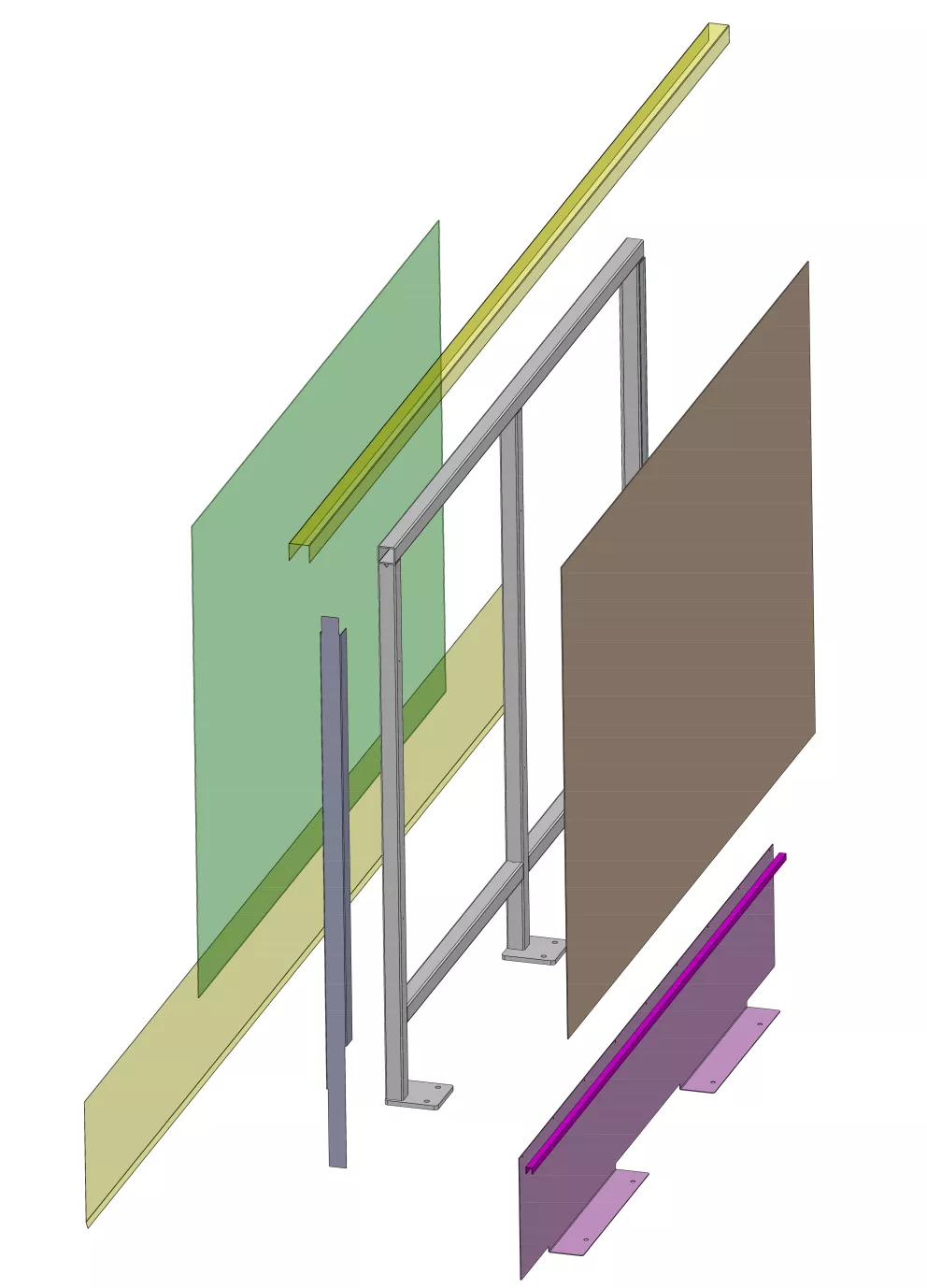

One of the decisive factors was having an excellent understanding of the possibilities offered by the prefabricated timber structure (a system developed and supplied at the time by the French company Houot Constructions). The designers planned a secondary steel structure to reinforce the original structure. This structure was designed to be as light as possible (to save materials) and to comply with current school building regulations. The system was developed so that it could be integrated directly into the building, without the need for a temporary support structure during construction. Although this operation was a little longer and more complex to put in place, it did limit material movements.

Figure 7. Assembly of the steel structure designed to reinforce the original timber frame of the 6000 wing. This is inserted directly into the original building, which meant that no temporary structure was needed during the deconstruction work.

Reclamation and reuse of building materials

The project presents various forms of reclamation and reuse, both on and off site, ranging from relatively simple and light operations to more complex realisations. Here's a brief overview:

- 88 light fittings salvaged from the 3000 wing and reused in the new library and in another wing of the Lycée (4000 wing).

- Nearly 52 running metres of shelving salvaged from a building site some twenty kilometres from the site. All the library furniture (tables and chairs) came from the same building. Additional furniture elements were made to measure by a craftsman who works with salvaged materials.

- 135 m² of road paving slabs reused for the landscaping of certain areas around the site and a cycle parking area. The pavers were delivered by the company in charge of the landscaping, which took care of dismantling, packaging, delivery and re-installation.

- Salvage and reuse of materials from the construction work, in particular for the construction of outdoor benches made from pallet wood and 38 prefabricated concrete elements used as channels. Various wood surface treatment methods were tested: flame treatment followed by the application of a protective coat and colouring over a base coat.

- 419 m² of plaster acoustic panels and 12 metal panels (4.3 m²) salvaged from the suspended ceilings in the 3000 wing. These elements were reused in the 6000 wing.

- Salvage of a batch of steel façade panels (partially painted green), then reused as railings for the new esplanade.

- 61 m² of sheet metal salvaged from the floors of the 3000 wing and reused as facade cladding for the 6000 wing. The painting was designed and produced by students from the school as part of their art education course.

- 11.8 tonnes of steel sections reclaimed from the dismantling of the 3000 wing structure and reused to build the new canopy.

Autres solutions

The project also features innovative forms of recycling. This is particularly true of the use of recycled aggregates from the deconstruction of the 3000 wing, which are used to produce the new concrete elements (in particular the floor slabs used for the landscaping of the outdoor areas).

Thanks to in-depth studies and laboratory tests, it was possible to increase the proportion of recycled aggregates used in the composition of the concrete to 60% (compared with 25% in the vast majority of recycled aggregate concretes).

Finally, the deconstruction of the 3000 wing was carried out selectively, taking care to sort the different flows of materials to ensure optimum recycling - for those fractions that could neither be maintained nor recovered for re-use.

This work was made possible by in-depth studies. These included a number of complementary aspects:

- A detailed inventory of reusable materials, supplemented by a large number of tests (often decisive in confirming or refuting the potential for reuse).

- A survey of pollutants.

- A more general inventory of the various waste flows anticipated, which enabled an optimal management plan to be drawn up.

Figure 23. Selective deconstruction of the 3000 wing. The various material flows are sorted at source to ensure optimum recycling, in accordance with the regulations on the hierarchy of waste management methods.

Les facteurs de la réussite

The success of these various ambitious and pioneering operations owes much to a cocktail of ingredients, often found in pilot projects of this type.

Gaining an awareness of the potential of the site

The project begins with a careful reading of the existing situation. This reading is based on a comprehensive approach, starting from the premise that there is intelligence, know-how and qualities in the construction systems inherited from our (not so distant) predecessors - even though these structures may no longer conform entirely to new normative frameworks. Backed up by forays into the history of construction (here, to understand the prefabrication systems of the original structures, for example), this reading reveals latent potential and makes the most of what's already there.

In the case of the present project, this type of reading has led to ideas such as retaining the 6000 wing to house a library, transforming the basement of the 3000 wing into a public terrace, and designing a custom-made canopy based on the steel structure of the 3000 wing.

Anticipation and flexibility

Because they break with the usual practices of the construction sector, circular construction approaches require excellent anticipation. This can be all the more complicated given that some of these solutions may also involve a degree of uncertainty (will a particular lot be able to be dismantled without damage? Will a particular material be available on the day it is needed? etc.).

For the clients piloting this type of project, it is essential to put in place a working framework that is both reassuring for all the stakeholders (giving clear directives, being explicit about expectations, making sure that everyone knows what he or she has to do, etc.) and flexible enough to seize opportunities and adapt to situations (falling back on one's feet if a batch cannot be reused, seizing an opportunity that arises at a given moment, etc.).

This delicate balance between anticipation and flexibility is largely achieved in the calls for tender and specifications: not only in the administrative and technical clauses, but also in the way the award criteria are formulated. In the case of the Lycée Michel Lucius project, innovative measures were taken to express, compare and assess the ecological value of the various bids. More broadly, this balance was also possible thanks to the involvement of the works management team, which was able to adapt to changing needs while giving a clear direction to this pioneering project.

Collaboration

Finally, a third decisive ingredient - which in a way results from the first two - is the atmosphere of constructive collaboration that must prevail among all the stakeholders. Nobody can implement a circular solution on their own. On the contrary, these solutions require excellent coordination between each link in the chain of operations.

To cite just a few examples from the Lycée Michel Lucius project:

On-site reuse operations required excellent coordination between the works management and the contractors in charge of the work (both deconstruction and re-installation). It was crucial to reach agreement on a series of essential aspects. Where does the work of one company end and that of the other begin? Where are the materials stored, under what conditions and for how long? Communication is essential to answer these kinds of questions and avoid them becoming obstacles to the smooth running of operations.

The reuse of materials, particularly when considered for structural purposes, involves good collaboration between project management, designers, control offices and contractors. Certain tests are necessary to ensure the fitness for use of the materials. It is important to determine which ones and how to interpret the results afterwards. Here too, a constructive attitude and a climate of trust are necessary to approach these questions with all the intelligence they require.

The Lycée Michel Lucius project demonstrates to what extent, when brought together, all these ingredients can contribute to changing the practices of the sector towards forms that are more respectful of material resources, the environment but also – and this is of course essential – of future users.

To go further

You can consult this document, edited by the Administration des Bâtiments publics:

Sophie Maurer (dir.), Économie circulaire dans la construction. Lycée Michel Lucius Luxembourg. Un projet pilote, Luxembourg, 2023, ISBN : 978-99987-716-1-1, 180 pages. Download link.

Credits

Project leader, design and execution

Client: Administration des bâtiments publics

Director: Jean Leyder (until 2021), Luc Dhamen

Project manager, architect: Sophie Maurer

Technical engineers: André Monien, Sergio Martins

Manager of the gardening department: Christian Stoos

Construction programme

Lycée Michel Lucius - International School

Director: Pascale Petry

Deputy Director: Robert Goedert

Design

Themes related to waste legislation: Administration de l’environnement

Themes related to public procurement regulation: Ministère de la Mobilité et des Travaux publics

Monitoring of the pilot project: Ministère de l’Environnement, du Climat et du Développement durable

Legal advice: Arendt et Medernach SA

Air conditioning, energy and technology consulting: EBP Schweiz

Advice regarding the sorting center: Superdreckskëscht

Design and execution

Architect: Schmets Architectes SARL

Civil engineering and exterior development engineer: Daedalus Engineering SAR

Deconstruction project engineer: Daedalus Engineering SARL

Sanitation consulting engineer: ENECO Consulting Engineers SA

Technical engineer: BLS Energieplan SARL

Safety and health coordinator, project and construction phases: SéQ Quality Safety Management SARL

Monitoring of the inventory and traceability of materials: Luxembourg Institute of Science and Technology

Control office: Luxcontrol ASBL

Approved body: Luxcontrol ASBL

Approved sanitation organisation: Secolux ASBL

Insurance broker: COO AlliA Insurance Brokers

Technical assistance: Beissel & Ruppert Engineering and Consulting SARL

Authorisations given by: Corps grand-ducal d’incendie et de secours, Inspection du Travail et des Mines, Ministère de l’Environnement, du Climat et du Développement durable, Service national de la sécurité dans la fonction publique, Ville de Luxembourg

Execution

Advice for concrete with recycled aggregates: Laboratoire de l’Administration des ponts et chaussées

Insurance: Baloise assurance

Construction trades

Deconstruction and exterior fittings: Entrapaulus construction SA

Structural work: Entreprise Poeckes SARL

Reinforcement (concrete with recycled aggregates): Trolux GmbH

Concrete work (recycled aggregate concrete): BHG Bauunternehmen GmbH, Trolux GmbH, Béton’s Concept SARL

Asbestos removal: SAT Lux SARL, UTG – Umweltschutz Technik Graf GmbH

Dismantling: Polygone SARL

Metal frame: CM-Attert SARL

Metal frame (Pergola): Kerger Constructions SA

Wooden frame: Prefalux SA, Efco-Forodia Exploitation SARL

Roofing: Jacobs & Sohn GmbH

Waterproofing: Alliance des Artisans

Metal carpentry: Mebolux SARL

Exterior carpentry: Fenster Eck SARL, Mebolux SARL

Exterior blinds and shutters: Technique Voile

Electrical installation: Electricity Watry SARL

Heating installation: Leonard sisters SARL

Plastering: Apleona R&M Ausbau Luxembourg SARL

Ironwork: MSN Maintenance Soudure Nucléaire SARL

Flexible floors: Revesol SARL

Interior wooden carpentry: TX-Objekt SARL

Wooden carpentry: Benu Village Esch ASBL

Painting: Peinture Feltus Dave SARL

Cleaning: Nettoservice SA

Scaffolding: Rende Grüstbau SARL, Alliance échafaudages SARL

Signage: Sign Consulting SARL

Supply of concrete with recycled aggregates: Bétons Feidt SA

Zero euro tender, salvage of furnishing objects from wing 3000: Benu Village Esch ASBL, Local Initiative and Management Center (CIGL) of Esch-sur-Alzette ASBL, Local Initiative and Management Center ( CIGL) of Differdange ASBL

- Soort

- Extraction In situ Integration

- Soort markt

- publiek

- Year

- 2021

- Adres

-

57, avenue Pasteur

Luxembourg Limpertsberg

Luxemburg - Copyrights

- © ABP : figures 10, 21. © Comed : figure 2. © Entrapaulus : figures 9, 15, 16, 19. © Levygraphie : figures 1, 4, 5, 7, 8, 12, 13, 14, 17, 18, 20, 22, 23. © LIST : figure 6. © MSN : figure 11. © Schmets Architectes : figure 3.